CHOOSING THE RIGHT CONCRETE CONVEYOR

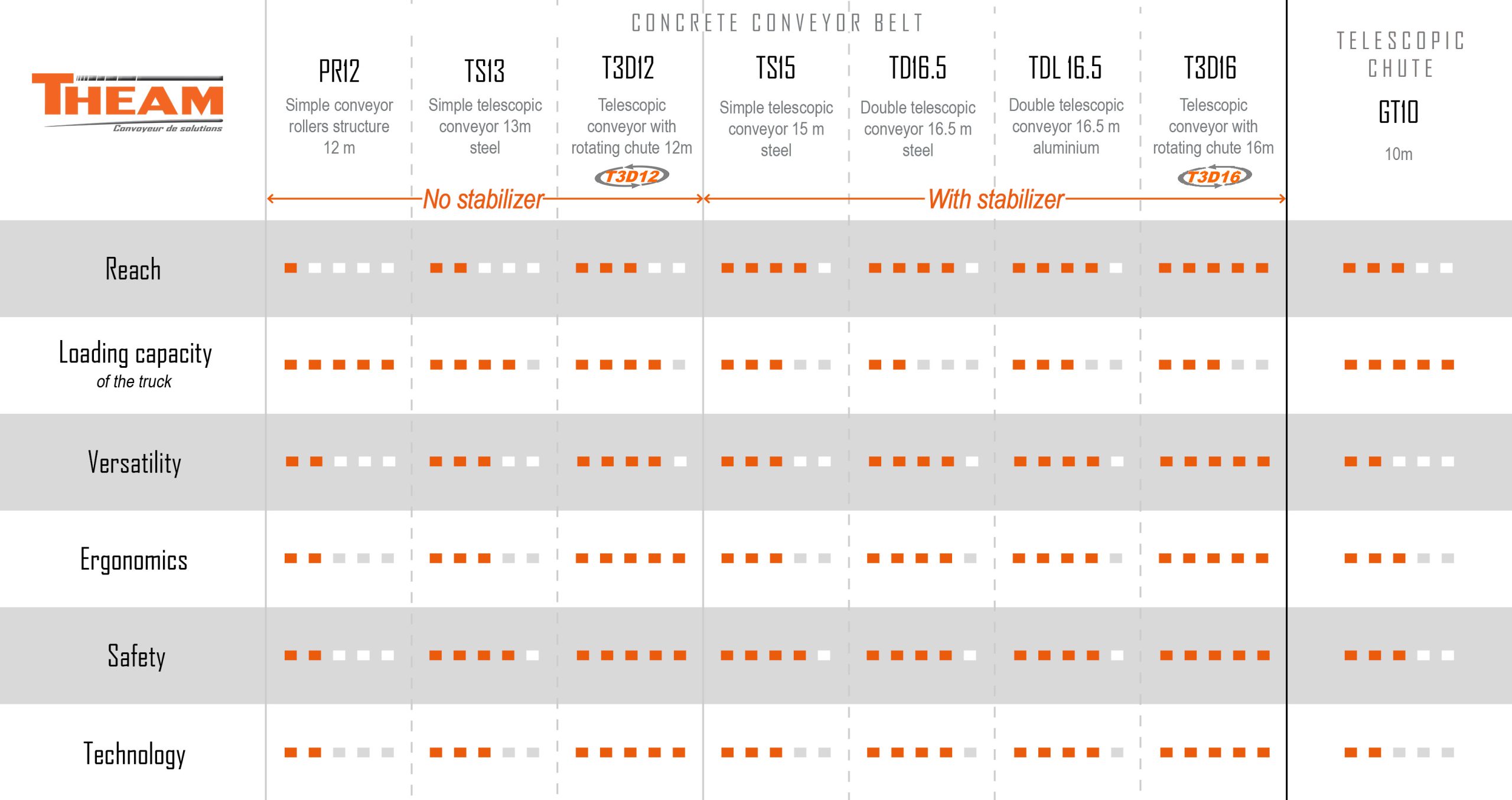

Our large range Theam Béton covers all types of needs when it comes to delivering concrete at a short or medium distance. The grid below was developed to help you choose the right conveyor depending on your own specific needs.

In order to understand how this ranking was created, and for more information about what’s behind each criterion, definitions are available following the grid.

ZOOM ON THE CRITERIA

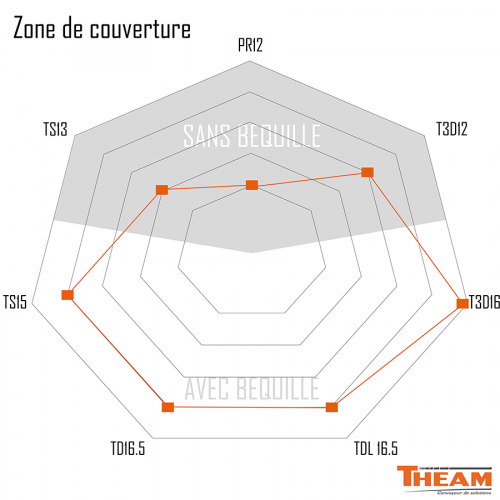

The reach corresponds to the surface the conveyor belt can cover without needing to move the truck.

It is calculated by taking into account:

- the maximum and the minimum distances that can be reached by the conveyor

- the maximum and minimum heights

- the rotation angle

The presence of a rotative chute (on conveyor belts T3D12 and T3D16) allows increasing the size of the area that is covered by the conveyor.

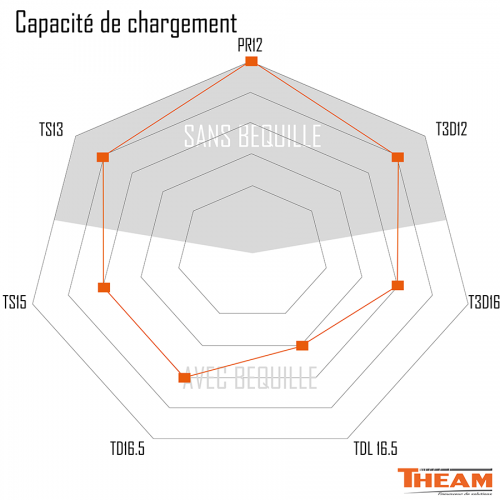

The loading capacity of the truck is impacted by the weight of the conveyor belt / telescopic chute. This weight varies depending on:

- the number of telescopes,

- the structure of the conveyor (steel or aluminium)

- the presence, or the lack of presence, of a stabilizer

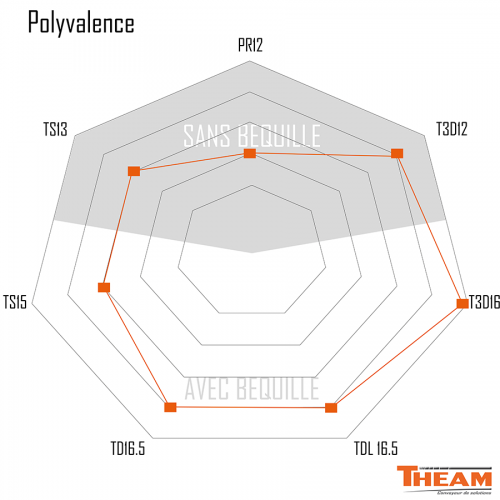

The concrete conveyor versatility depends on :

- the type of materials that can be transported (concrete only, concrete and gravels, etc.)

- the types of concrete the conveyer can carry (fiber-reinforced concrete or not, plasticity, fluidity, etc/)

- the different types of work sites you can go to with your conveyor / the various possible applications (ground floor only, storeys, sloping ground, etc.)

- the presence, or the lack of presence, of stabilizers,

- the number of telescopes

- the rotation system

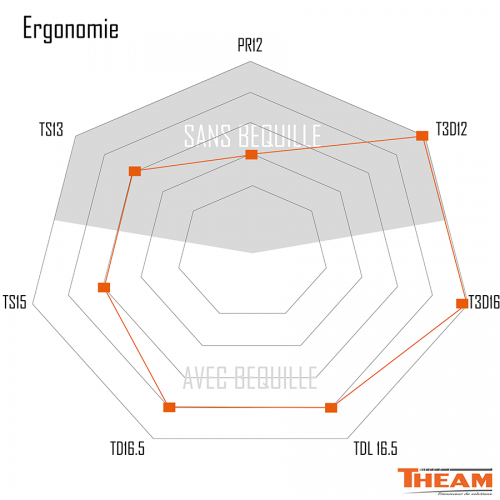

All the Theam products allow you to gain comfort on your work sites. However, this comfort may change depending on the conveyor belt / telescopic chute you choose because it depends on the following elements:

- the radio system control (it is not necessary anymore to go up and down the truck cabin repeatedly)

- the presence, or not, of a high-pressure washer (makes cleaning your equipment easier)

- the number of telescopes (allows you to go further)

- the presence of a rotative chute or not (increases the reach and reduces the number of movements of the truck)

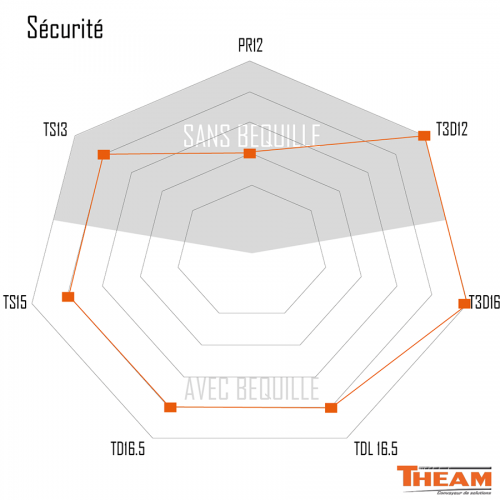

Theam has made safety on the worksite one of its priorities. Logically, our products bring you an undeniable level of safety thanks to

- the radio-control system: by limiting the times the driver needs to go up and down the cabin, it reduces the number of accidents.

- locking the pivot during transport

- the telescope(s)

- the roller protection

- the stability

Moreover, all of our concrete conveyor belts are subject to a bodywork study and are CE certified.

Additional options, such as the high voltage sensor or the stabilizer sensor can add even more safety.

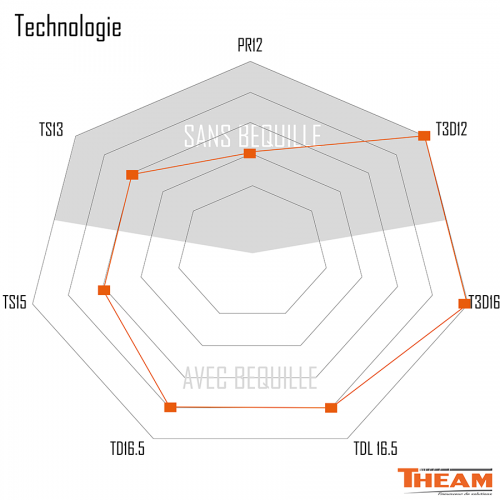

Theam’s know-how allows developing technical products. The technology available in our conveyor belts and telescopic chutes allows reaching a level of performance no one reached before.

would you like to talk with a specialist and get personalized advice?

Feel free to call us at +33 2 40 65 22 10 or to send us an email at contact@theam.com. You may also find a distributor in your area on our Distributors Network page.